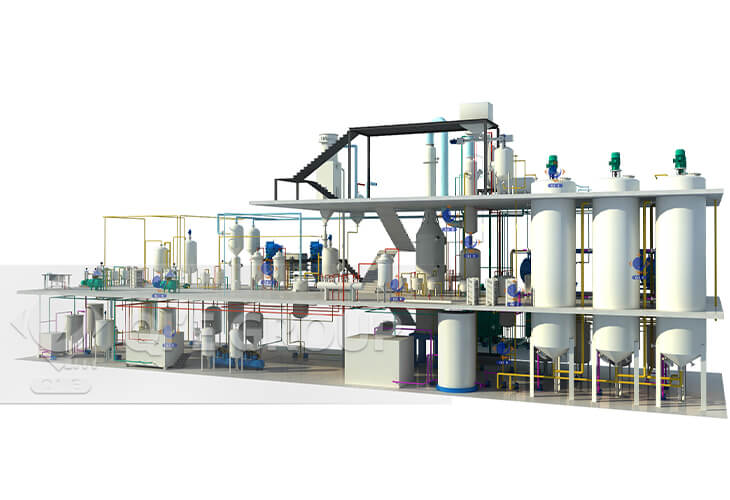

In the realm of peanut oil production, screw pressing technology has emerged as a game - changer. The core advantage of screw pressing lies in its ability to achieve high - efficiency and stable production through an integrated process. This process includes cleaning, crushing, steaming, and finally, pressing. By doing so, it can significantly boost the oil extraction rate while maintaining the purity of the oil.

The workflow of screw pressing is a well - orchestrated sequence. First, the peanuts are cleaned to remove any impurities. Then, they are crushed into smaller pieces to increase the surface area for better oil extraction. After that, the crushed peanuts are steamed to further break down the cell structure. Finally, the screw press applies pressure to extract the oil. According to industry data, screw presses can achieve an oil extraction rate of up to 90%, which is much higher than traditional methods.

There are two main peanut oil pressing processes: hot pressing and cold pressing. Each has its own unique application scenarios, and temperature control plays a crucial role in determining the flavor, nutrient retention, and market positioning of the oil.

Hot pressing involves heating the peanuts to a relatively high temperature (usually around 120 - 130°C) before pressing. This method can extract more oil and produce a peanut oil with a strong, rich flavor. However, the high temperature may destroy some of the nutrients in the oil. Hot - pressed peanut oil is often favored in markets where consumers prefer a more intense flavor, such as in some Asian countries.

Cold pressing, on the other hand, is carried out at a lower temperature (below 60°C). This process helps to retain more nutrients in the oil, such as vitamin E and unsaturated fatty acids. Cold - pressed peanut oil has a milder flavor and is often targeted at health - conscious consumers. For example, in Western markets, cold - pressed oils are becoming increasingly popular due to their perceived health benefits.

For optimal flavor and nutrient retention, a steaming temperature of 90°C is recommended. This temperature can balance the need for breaking down the cell structure and preserving nutrients.

In the actual operation of peanut oil production, there are several common problems. One of them is the fluctuation of material moisture content. If the moisture content is too high, it can affect the oil extraction rate and the quality of the oil. To solve this problem, it is recommended to use a moisture detector to monitor the moisture content of the peanuts in real - time and adjust the steaming process accordingly.

Another problem is the wear of the screw. As the screw is the key component of the press, its wear can lead to a decrease in the oil extraction rate and an increase in energy consumption. To address this issue, a wear - detection system can be installed to provide early warnings. Regular maintenance and replacement of the screw can also extend its service life.

In the era of green manufacturing, screw pressing technology also shows its advantages in energy - saving and environmental protection. Compared with traditional pressing methods, screw presses consume less energy. For example, a modern screw press can save up to 30% of energy during the pressing process. Additionally, the waste generated during the screw - pressing process can be recycled and used as animal feed or fertilizer, which reduces environmental pollution.

Q: What is the best moisture content for peanuts before pressing? A: The ideal moisture content for peanuts before pressing is around 8 - 10%.

Q: How often should the screw be replaced? A: It depends on the usage frequency and the quality of the screw. Generally, it is recommended to replace the screw every 1 - 2 years.

If you want to learn more about the details of the screw - pressing equipment or obtain a process optimization manual, please visit CTA - URL. Discover how you can optimize your peanut oil production process and enhance your market competitiveness.