For small-scale peanut oil producers, achieving consistent high yield while maintaining premium quality remains a persistent challenge. Traditional pressing methods often result in oil recovery rates below 78%, leaving valuable nutrients and economic potential untapped. That’s where modern screw press technology comes in — not just as an upgrade, but as a strategic shift toward efficiency, purity, and sustainability.

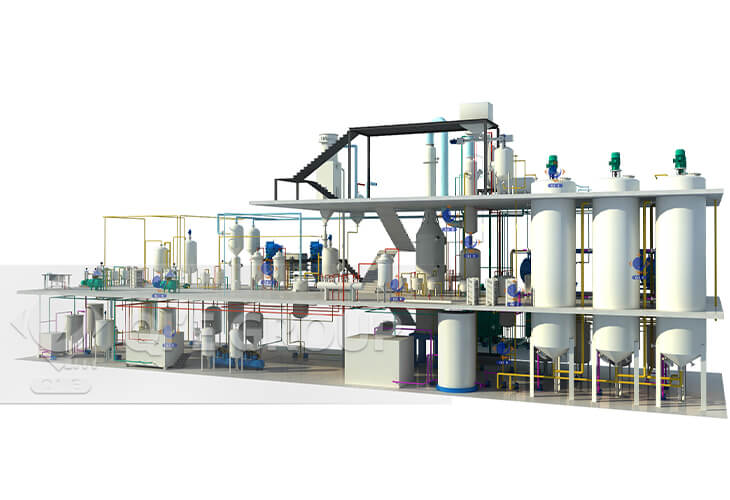

The core of this advancement lies in its seamless integration of four key stages: cleaning, crushing, steaming (or tempering), and pressing. Unlike fragmented processes that lose heat and moisture control, the screw press system ensures precise temperature gradients across each phase — critical for maximizing oil extraction without compromising clarity or flavor.

In real-world operations, farms using this method report average oil yields of 83–87% — up to 9% higher than older hydraulic presses. This isn’t just about more oil; it’s about cleaner separation between oil and solids, reducing downstream refining costs by 15–20%.

Understanding the difference between hot and cold pressing is essential for market positioning. Hot pressing (typically at 90–110°C) delivers higher yields and better shelf stability due to reduced free fatty acids — ideal for commercial kitchens and foodservice providers. Cold pressing (below 45°C) preserves natural antioxidants like vitamin E and phytosterols, appealing to health-conscious consumers in North America and Europe.

A recent survey of 300+ processors found that 68% of users who switched to screw press systems reported improved consistency in both yield and sensory attributes — whether they chose hot or cold processing. This flexibility makes the technology future-proof for evolving consumer demands.

Even with advanced machinery, success depends on fine-tuning parameters such as feed rate, screw speed, and steam pressure. For instance, increasing the steam temperature by 5°C during tempering can boost oil release by 3–5% — but only if moisture content stays within 6–8%. Over-drying leads to brittle meal and lower extraction efficiency.

Maintenance matters too. Regular checks on wear plates and bearing alignment prevent vibration-induced inefficiencies. One factory in Nigeria saw a 12% drop in downtime after implementing a monthly preventive maintenance schedule based on manufacturer guidelines.

With global regulations tightening around energy use and emissions, especially in EU and ASEAN markets, screw press systems offer clear advantages. They consume up to 25% less electricity per ton of oil compared to older models, aligning with green manufacturing goals and enhancing brand reputation.

Whether you're scaling up production or optimizing existing lines, adopting this technology means investing in smarter, cleaner, and more profitable operations — without sacrificing quality or compliance.

Ready to explore how your facility can benefit? Get our free Process Optimization Guide — filled with case studies, parameter tables, and step-by-step setup tips tailored for small-to-midsize peanut oil producers worldwide.

Download Your Free Process Optimization Guide Today