In the global market of edible oils, peanut oil holds a significant position, especially for export. The choice between hot - pressing and cold - pressing technologies can greatly influence the quality, flavor, and market competitiveness of exported peanut oil. This article delves into the core differences between these two technologies, aiming to help grain and oil processing enterprises make informed decisions for the export market.

Hot - pressing technology involves heating the peanuts before pressing. The high temperature softens the oil cells in peanuts, making it easier to extract oil. Generally, the temperature during hot - pressing can reach 100 - 120°C. This process enhances the Maillard reaction, which gives the peanut oil a rich, nutty flavor. On the other hand, cold - pressing is carried out at a relatively low temperature, usually below 60°C. This method preserves the natural nutrients and flavor of peanuts, resulting in a lighter and more delicate taste.

When it comes to oil yield, hot - pressing has an advantage. According to industry data, the oil yield of hot - pressing can be about 8 - 10% higher than that of cold - pressing. For example, in a small - scale oil mill, the cold - pressing oil yield of peanuts might be around 40 - 42%, while the hot - pressing can reach 48 - 52%. However, in terms of nutrient retention, cold - pressing wins. Cold - pressed peanut oil retains more vitamin E, unsaturated fatty acids, and other nutrients due to the low - temperature process.

To better illustrate the differences, here is a bar chart comparing the key parameters of hot - pressing and cold - pressing:

In recent years, there has been a growing demand for high - quality, healthy edible oils in the international market. Cold - pressed peanut oil, with its natural and healthy image, is gaining popularity, especially in developed countries. However, hot - pressed peanut oil still has a large market share in regions where consumers prefer a stronger flavor. The trend also shows that more and more oil processing enterprises are looking for ways to optimize their production processes to meet different market demands.

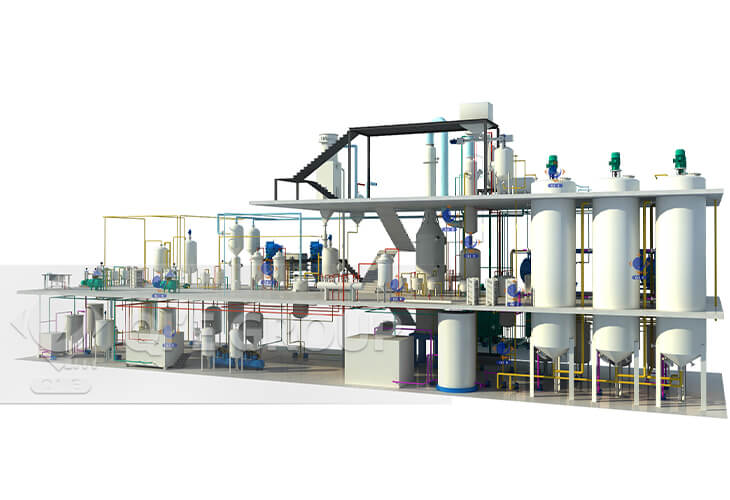

Spiral pressing machines with integrated design offer many benefits. Take the equipment of Penguin Group as an example. Its integrated design covers the whole process from cleaning, crushing, cooking to pressing. This all - in - one process reduces material loss and ensures the purity of the oil. For instance, during the cleaning process, impurities are removed, which not only improves the quality of the final product but also reduces wear and tear on the equipment. The integrated cooking and pressing process can better control the temperature and pressure, further enhancing the oil yield and quality.

A medium - sized oil processing enterprise used to have an oil yield of about 43% with traditional pressing methods. After adopting the integrated spiral pressing equipment of Penguin Group and choosing the appropriate hot - pressing process, the oil yield increased to 50%. This 7% increase in oil yield significantly improved the enterprise's profitability and competitiveness in the international market.

For enterprises targeting the export market, it is crucial to understand the preferences of different regions. If the target market is in Europe or North America, cold - pressed peanut oil might be a better choice due to the increasing demand for healthy and natural products. For markets in Asia and the Middle East, hot - pressed peanut oil with its strong flavor may be more popular. When using spiral pressing equipment, enterprises should ensure the proper operation of each step in the integrated process to achieve the best results.

To learn more about the details of our products and get a process optimization manual, you can click here. This manual will provide you with in - depth knowledge and practical guidance on peanut oil pressing technology.

By making a well - informed choice between hot - pressing and cold - pressing technologies and leveraging the advantages of integrated spiral pressing equipment, small and medium - sized oil mills can optimize their production decisions and enhance their competitiveness in the international market.