The edible oil industry is undergoing a significant transformation, with green energy - saving technologies becoming a new benchmark. In this context, Penguin Group's peanut oil press for small factories has emerged as an innovation, leveraging advanced screw pressing technology. This article will delve into the details of this technology, compare thermal and cold - pressing processes, and explore how these industry trends benefit foreign trade enterprises.

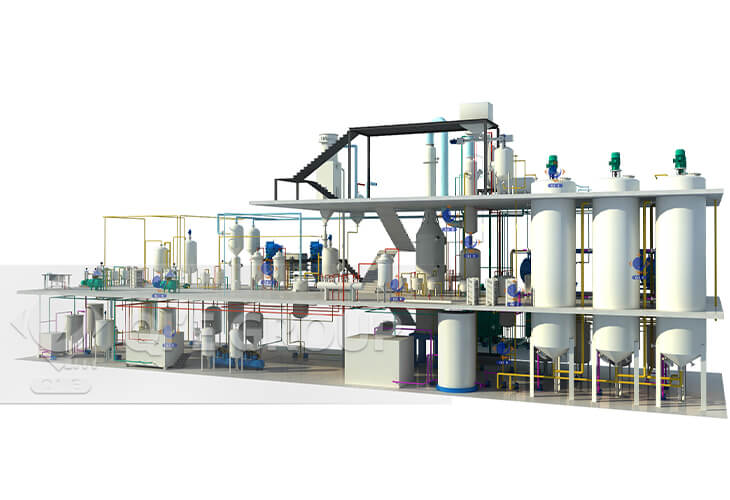

Traditional peanut oil pressing techniques often suffer from low efficiency, high energy consumption, and inconsistent oil quality. Penguin Group's screw pressing technology addresses these issues. It integrates cleaning, crushing, steaming, and pressing into one seamless process. As shown in Figure 1, this integrated approach can increase the oil yield by up to 10% compared to traditional methods, while also reducing energy consumption by approximately 15%. The technology ensures the purity of the oil by effectively removing impurities during the cleaning stage.

Thermal and cold - pressing are two common processes in peanut oil production, each with unique characteristics. Thermal pressing involves heating the peanuts before extraction. This process can extract more oil, typically achieving a 90% - 92% extraction rate. The oil produced has a rich, nutty flavor, appealing to consumers who prefer a stronger taste. However, the high - temperature treatment may destroy some of the nutrients in the oil.

On the other hand, cold - pressing is carried out at lower temperatures, usually below 60°C. Although it has a lower extraction rate, around 85% - 88%, it preserves more of the natural nutrients and vitamins in the peanut oil. The resulting oil has a lighter, more delicate flavor, which suits health - conscious consumers. Figure 2 provides a clear comparison of these two processes.

To optimize the peanut oil production process, controlling the moisture content of the peanuts is crucial. The ideal moisture level for peanuts before pressing is between 6% - 8%. Adjusting key parameters such as pressing speed and pressure can also significantly affect the oil yield and quality.

With the global emphasis on sustainable development, green manufacturing policies have been introduced in many countries. Energy - saving peanut oil pressing technology not only meets these environmental requirements but also offers cost - saving benefits for foreign trade enterprises. By adopting these technologies, enterprises can reduce production costs by 10% - 15% in the long run, enhancing their competitiveness in the international market.

In summary, Penguin Group's innovative peanut oil pressing technology represents the future of the industry. It combines high efficiency, energy - saving, and adaptability to different market demands. Whether you're a technical personnel in the grain and oil processing industry or a purchasing decision - maker, these technologies can help you improve your production process and boost product competitiveness. Learn more about the equipment details and get the process optimization guide.

For more in - depth information and technical support, please visit the official website of Penguin Group. The continuous innovation and development in the industry await your exploration!